11.07.2025 Our people

IRIS 24 Telerobot: Enhancing Safety and Efficiency in Nuclear Power Plant Maintenance

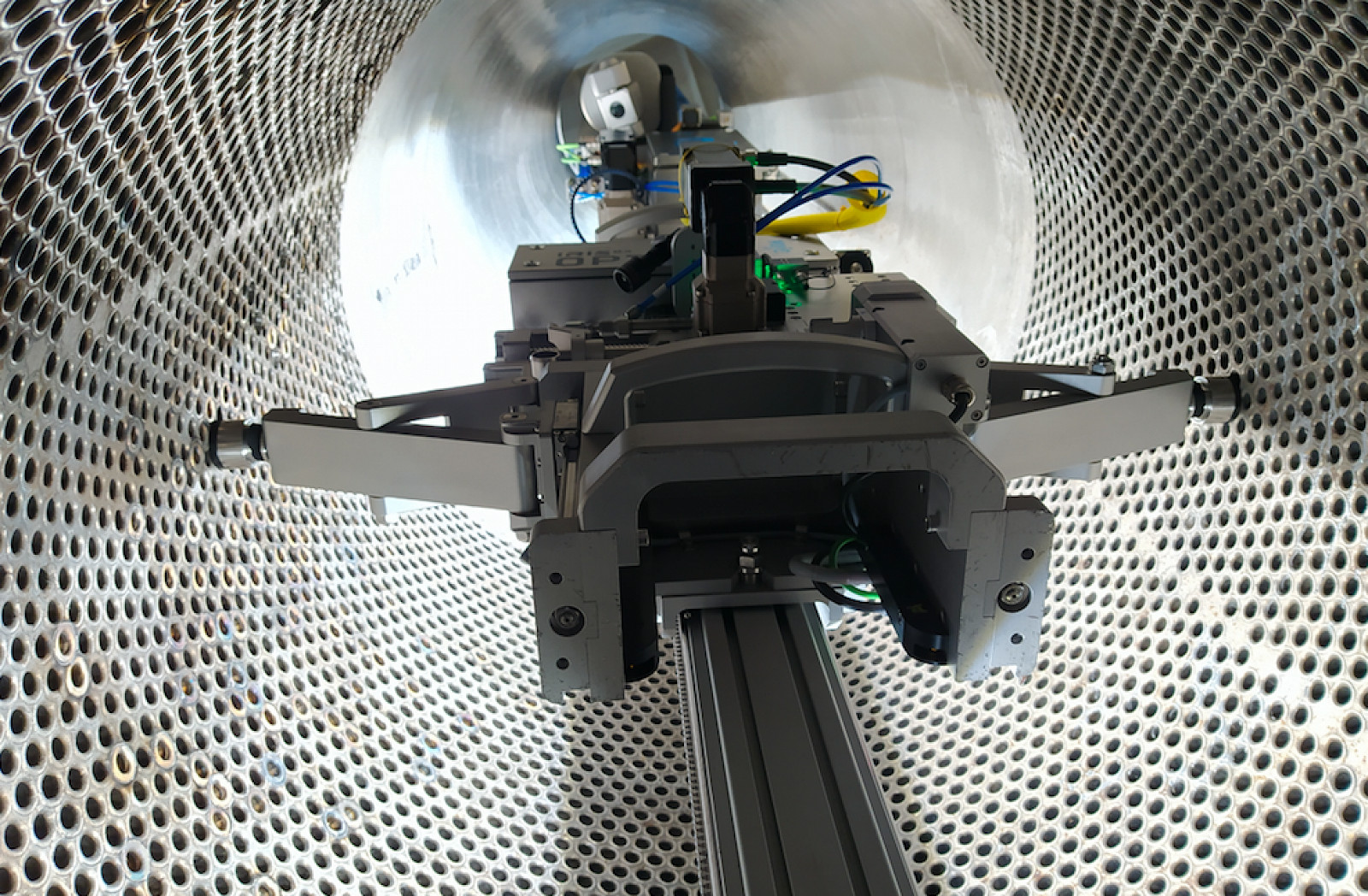

The IRIS 24 telerobot is a state-of-the-art system designed for the inspection and plugging of heat-exchanger tubes inside steam generators during scheduled outages. It significantly increases the efficiency, precision, and—most importantly—the safety of maintenance operations on key components within nuclear reactor units.

This advanced device was developed and manufactured by specialists from the Division for Diagnostics of Nuclear Power Components at VUJE, a.s., specifically for the Khmelnytskyi Nuclear Power Plant in Ukraine. More than 40 experts from VUJE contributed to its development and production, including mechanical engineers, electrical engineers, software developers, non-destructive testing specialists, and welding professionals. The entire development process took approximately 14 months.

"Our team has developed a device that not only meets the highest nuclear safety standards but also integrates multiple functions into a single system. That's something unique on the market," said Adrian Kovalyk, Director of the Division for Diagnostics of Nuclear Power Components at VUJE.

System Capabilities and Innovations

The IRIS 24 telerobotic system features:

- A modular design, allowing various modules to be easily interchanged and combined based on operational needs

- A control system developed entirely by VUJE's internal engineering team

- Water resistant, high-performance next-generation actuators

- An integrated measurement system, capable of detecting material defects as small as 1 mm

The telerobot performs eddy-current testing on heat-exchanger tubes and is capable of plugging defective ones within the same operational cycle. With high precision, it identifies even the smallest cracks among the 11,000 tubes in the steam generator, assesses their depth and shape, and automatically plugs the damaged tubes.

"It is a unique system that combines both diagnostics and maintenance on a single platform. No other solution currently offers this level of integration," noted Adrian Kovalyk, proud of the development team.

Training and Certification for Ukrainian Staff

The IRIS 24 telerobot was delivered to the Khmelnytskyi Nuclear Power Plant at the end of June 2025. As part of the first project phase, VUJE provided training for 38 Ukrainian staff members, including analysts, technicians, operators, and welders. The two-week training program concluded with comprehensive functional testing, confirming the system's readiness for operational deployment.

The next phase involves the certification of both the technology and the trained personnel. This will be conducted under the supervision of the relevant certification authority and the Ukrainian nuclear regulator and is scheduled for January 2026. Once certified, the IRIS 24 system will be deployed during the plant's next planned outage.

Built on a Legacy of Innovation

The IRIS 24 project builds upon VUJE's extensive experience with similar systems supplied to nuclear power plants in Slovakia, the Czech Republic, Ukraine, and Hungary. Compared to the previous generation developed between 2017 and 2020, the new system represents a significant leap forward in terms of technology and performance.

"For us, this is not just the successful completion of a project, but also a springboard for the future development of telerobotic systems aimed for inspection of critical nuclear power plant components," concluded Adrian Kovalyk on behalf of the Division for Diagnostics of Nucelar Power Components at VUJE.