11.03.2022 Our people

Look behind the scene and see how a unique training manipulator came about IRIS-V (photo report)

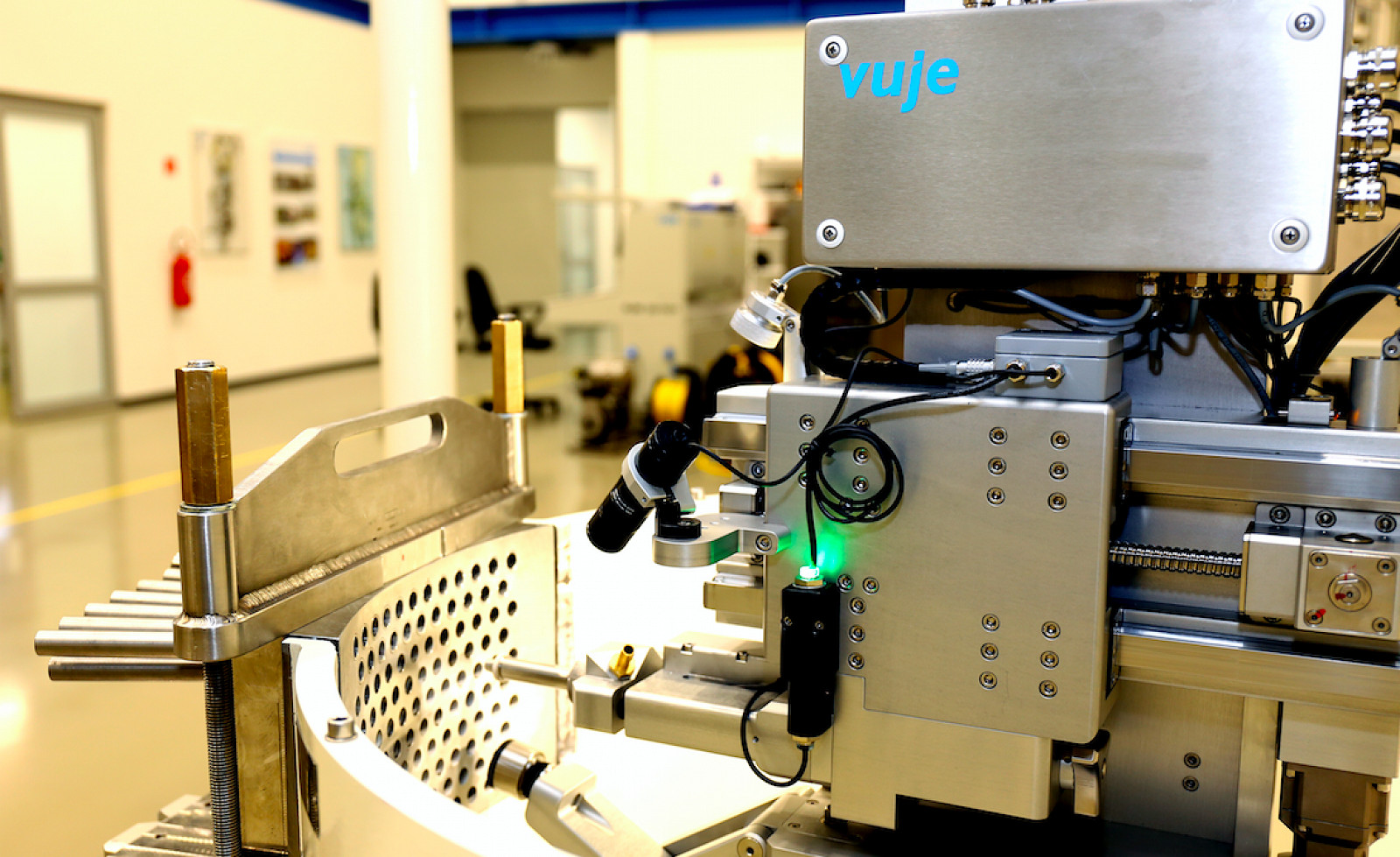

VUJE is the author of a unique training manipulator be one of a kind in Europe. Primarily requested by the Czech energy company CEZ group, it has been deployed in the nuclear power plant training centre Temelin. We offer you the photo reports behind-the-scenes of developing this unique equipment called IRIS-V, which is an example of remarkable advance in the field of remote-controlled equipment for the nuclear power plants (NPP).

Specially designed training manipulator IRIS-V facilitates the training of personnel. It is identical to manipulators used in the NPP operation for checking the steam generators. Thanks to this complex equipment, the space with radiation does not need to be attended by the personnel. By training and improving the skills the personnel can become experts first and prior to visiting the real workplace.

In the hands of experts

The process of development until the first trial lasted 12 months. The team of experts was led by Pavol Jablonický, Head of the Design and Development Department in VUJE, a. s., who has been engaged in the remote-controlled manipulators for 35 years, especially in non-destructive repairs of the main components of the nuclear power plants both in Slovakia and abroad. He claims the following: "From the viewpoint of capabilities and functions of the device we are thoroughly confident that no company in Europe or worldwide has such solution on offer. We are altogether exceptional by exhaustive offer and complete delivery”.

Proud of the team

Outstanding project was supervised by Adrian Kovalyk, Member of Board of Directors and Director of Division for Diagnostics of the Nuclear Power Plants. He is truly satisfied with the colleagues striving for the science, and as well with the progressive philosophy of CEZ, a. s. that came up with the idea of training manipulator. He asserts; „Forwarding a quality training of the stuff, the CEZ group set an example worth to be followed by other nuclear power plant operators. We are proud to be a part of, as well as our portfolio of equipment scaled up.

In brief about Training Manipulator IRIS-V

- First training manipulator and one of a kind in Europe

- Identical to IRIS manipulators used in operation

- Used to train personnel in “clean” area

- Developed by 21-member team

- Deployed in the nuclear power plant training centre Temelin

- Process of development and deploy lasted 12 months

Attractive photo reports on IRIS-V Development:

STOJA ZA ZRODOM IRIS-V: (from the left below) Ján Molitoris, Tomáš Lehuta and Juraj Bokora, (from the left above) Ondrej Haršányi, Zuzana Silberhorn, Pavol Jablonický, Richard Zdarilek, and Adrian Kovalyk, Director of Division for Diagnostics of the Nuclear Power Plants.

STOJA ZA ZRODOM IRIS-V: (from the left below) Ján Molitoris, Tomáš Lehuta and Juraj Bokora, (from the left above) Ondrej Haršányi, Zuzana Silberhorn, Pavol Jablonický, Richard Zdarilek, and Adrian Kovalyk, Director of Division for Diagnostics of the Nuclear Power Plants.

IN FRONT OF MANIPULATOR WITH CONTROL UNIT: Head of the Design and Development Department Pavol Jablonický with Tomáš Lehuta, and Milan Ťažký, a mechanic, and Ján Molitoris, a constructor, and Adrian Kovalyk, Director of Division for Diagnostics of the Nuclear Power Plants.

IRIS-V IN TEST STAND WITH OPZ MODULE V SKÚŠOBNOM STENDE S NASADENÝM MODULOM OPZ: Pavol Jablonický, Head of the Design and Development Department and Adrian Kovalyk, Director of Division for Diagnostics of the Nuclear Power Plants pride themselves on one and only manipulator accomplished in VUJE workroom.

VUJE SITE: Everything is ready for delivery to the customer.

VUJE SITE: Everything is ready for delivery to the customer.