19.08.2021 Our Media Coverage

Slavomír Bebjak, Branislav Hatala, Vladimír Slugeň and their current view on the ALLEGRO Project

The ALLEGRO Project represents a prototype of a gas-cooled experimental reactor working with fast neutron spectrum. The construction of the ALLEGRO demonstrator represents an important step in the next stage of the Generation IV reactors construction.

Important part of this phase is to get an experimental data using research facilities, such as the STU experimental helium loop, as well as to perform a large number of safety analyses necessary for the investigation of physical phenomena and processes of the ALLEGRO demonstrator. The ongoing SafeG project, which aims to solve an open issues in the concept of safety of gas-cooled fast reactors (GFR) and the design of key safety systems of the ALLEGRO demonstrator, also contributes to this goal.

ALLEGRO – the 4th generation gas-cooled fast reactor demonstrator

ALLEGRO is one of the six representatives of the so-called 4th generation reactors. Within the European research, Slovakia has a unique chance together with the Czech Republic, Hungary, Poland, France, as well as other countries to significantly participate in its construction. In the first step, it is necessary to create a corresponding technological platform and activate people in our country and abroad who are interested in solving challenging technical tasks. ALLEGRO is also a chance for Slovakia to return to the real path of technical and economic development. It can restart the technical and technological knowledge base on which other industries would build. It may be an area for capitalizing on our previous experience with the construction and operation of nuclear facilities. It will contribute to the closure of the fuel cycle and to the reuse of irradiated fuel, which forms a substantial part of radioactive waste. It gives an opportunity to create hundreds of new jobs and a chance to participate in excellent research for many Slovak companies.

The construction of the gas-cooled reactor ALLEGRO assumes a construction of a technological platform and investments in mechanical engineering, chemistry or electrical engineering in the first or maybe the following ten years. In education, this would require a stronger inclination of a talented young generation to the natural and technical sciences. However, this will only happen if young people see real opportunities to find employment in technical disciplines.

In order to assure energy requirements of the future, ten countries, such as Argentina, Brazil, Canada, France, Japan, the Republic of Korea, South Africa, Switzerland, the United Kingdom and the United States (EURATOM joined in 2003 and China and the Russian Federation in 2006), have established Generation IV International Forum - GIF and launched an international framework cooperation in research of the next generation nuclear energy systems known as Generation IV. These systems may be licensed, designed and operated in order to ensure competitive prices and reliable energy production while adequately solving issues of nuclear safety, waste, non-proliferation of nuclear materials, and public opinion.

The task of the Generation IV nuclear energy systems was to ensure their international commissioning around the year 2030, when most nuclear power plants, currently in operation, will be at the end of their design lifecycle [1]. The nuclear energy research programmes around the world have individually developed concepts that have helped to form the basis for the Generation IV systems. Increased R&D cooperation, to be carried out by GIF countries, will stimulate the progress towards the implementation of individual systems.

Based on international obligations and joint determination, the world will be able to utilize the benefits of the Generation IV nuclear energy systems over several decades. At the beginning of this century, the GIF forming countries started a discussion on research that would lead to the next generation of reactors. From the initial talks, they undertook to develop a technology plan to guide the global efforts, which was confirmed by supporting the development of a comprehensive technology plan, which became its main goal. More than a hundred scientists and experts from the selected countries were invited to take part in its preparation.

Based on the goals defined for the Generation IV project, 6 reactor concepts were specified for further development, a brief overview of which is given in Table 1. The reactor concepts are as follows:

- VHTR –Very-high temperature reactor,

- SFR – Sodium-cooled fast reactor,

- SCWR – Supercritical water-cooled reactor,

- GFR – Gas-cooled fast reactor,

- LFR – Lead-cooled fast reactor,

- MSR – Molten salt reactor.

Table 1: Overview of the perspective Generation IV reactor concepts [2].

|

System |

Neutron spectrum |

Coolant |

Coolant temperature at the outlet (°C) |

Fuel cycle |

Electric output (MWe) |

|

VHTR |

thermal |

helium |

900-1000 |

open |

250-300 |

|

SFR |

fast |

sodium |

550 |

closed |

30-150, |

|

SCWR |

thermal/fast |

water |

510-625 |

open/ closed |

300-700, |

|

GFR |

fast |

helium |

850 |

closed |

1200 |

|

LFR |

fast |

lead |

480-800 |

closed |

20-180, |

|

MSR |

thermal/ epithermal |

fluoride salts |

700-800 |

closed |

1000 |

The main criterion for the selection of the perspective reactors was the fulfilment of 8 objectives specified by GIF. However, each Member State was found to have different priorities in the use of the Generation IV reactors. Based on these facts, three main areas of interest for the use of the Generation IV reactors have been identified. These are as follows:

- electric energy production,

- production of hydrogen and heat for industrial application

- actinide management.

The production of electric energy is the basic task of the current nuclear reactors, so it is obvious that for this purpose it will remain unchanged for the future reactor concepts and can be applied to all Generation IV systems. In order to be able to use the Generation IV reactors also for heat supply for industrial applications, a high coolant outlet temperature from the reactor core is required, preferably above 700 °C [3]. The VHTR, GFR, MSR and LFR reactors provide this possibility. Actinide transmutation is a characteristic feature of fast reactors due to the use of a fast neutron spectrum and a high neutron flux density. Except for VHTR, all reactor concepts can be used for actinide transmutation. This is obvious for three fast reactors, however the MSR reactor, which operates in thermal and epithermal neutron spectra, is a suitable candidate due to its good neutron balance. The basic concept of SCWR assumes operation in thermal spectrum of neutrons, however when removing the moderator from the reactor core, it can also be operated in the fast neutron spectrum.

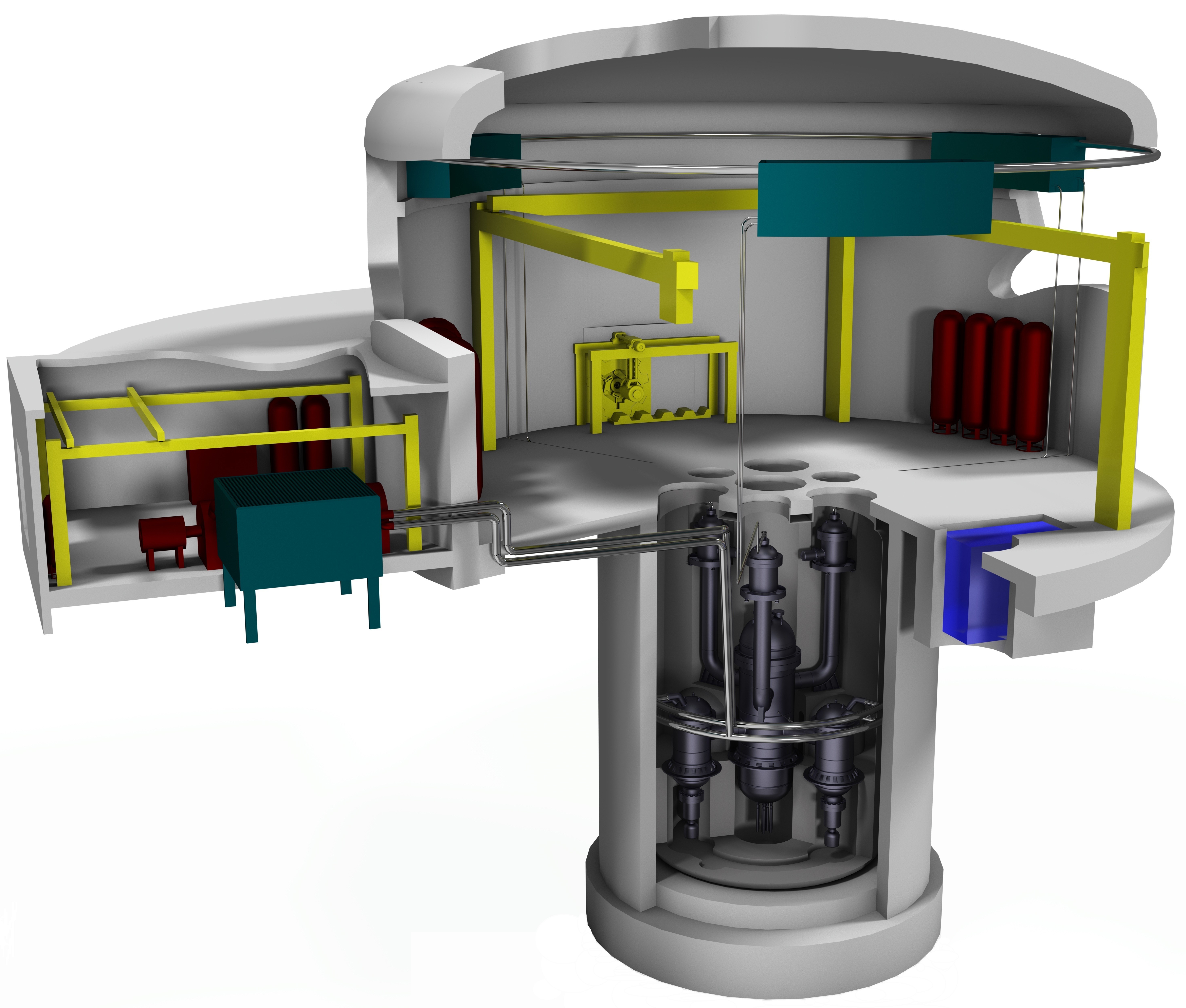

A necessary step in the development of a commercial reactor based on GFR technology is the construction of an experimental demonstration reactor for fuel qualification and for the verification of safety systems specific to GFR technology. The proposed GFR demonstration reactor is ALLEGRO - a low-energy reactor capable of operating with different core configurations, starting with MOX steel-cladding fuel and then ceramic fuel, at which an outlet temperature of up to 850 °C can be reached. The cross-section of its model is shown in Figure 1, its technical scheme is shown in Figure 2.

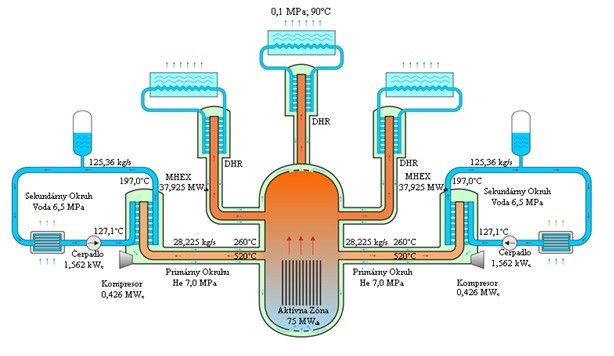

The basic concept of the ALLEGRO reactor was designed by the French organization CEA. The thermal output of the ALLEGRO reactor should be 75 MW, without electric energy production. The heat in the heat-exchanger is from the primary circuit transferred to the secondary circuit and from there to the atmosphere. The ALLEGRO Project represents the world's first gas-cooled reactor working with a fast neutron spectrum. The reactor will continue to serve as a scientific and research centre, which is necessary in the next stage of the Generation IV reactor construction.

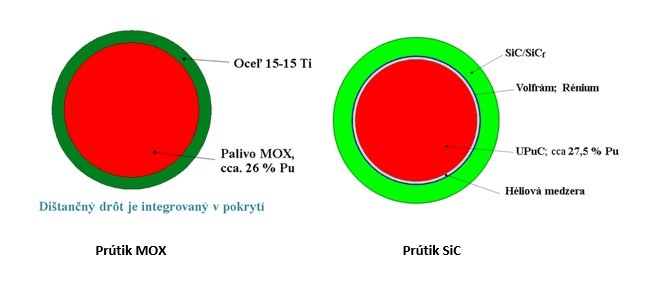

The ALLEGRO demonstrator will have a different fuel composition in the reactor core during its operation. The first, starting core (“MOX core”), will use the existing technology (assembly containing MOX fuel pin with metal cladding). The MOX ALLEGRO core is based on MOX fuel pin technology, 15-15 Ti steel cladding (class AIM1) and a sheath wire, which have been developed for sodium fast reactors. The second, "ceramic" core (U-Pu carbide pellets inside the SiCf / SiC cladding), will be used to test the new fuel design and to test the overall design of the gas-cooled reactor under very high temperature (850 °C). From a safety point of view, the ceramic fuel will be better than MOX fuel as it melts at higher temperatures.

The starting fuel assembly consists of 169 pins surrounded by a steel (15-15 Ti) casing tube of a hexagonal shape, 0.2 cm thick. The fuel assembly pitch is 11.08 cm in a cold state, i.e. at the temperature of 20 °C. The size of the pitch between the assemblies is 0.15 cm. Helium as a coolant reaches a pressure of 7 MPa under operating conditions, i.e. 260 °C at the inlet and 535 °C at the outlet. The core contains 81 MOX assemblies and 6 experimental positions for testing the new ceramic fuel.

The concept of a fuel pin assembly based on carbide fuel can be derived from the initial design of the GFR power reactor. The design criterion was a linear power of 164 W/cm. In case of carbide fuel, it was not possible to design an assembly concept with a spacer wire as the properties of the SiC/SiCf cladding material do not allow the spacer wire to be used and it is difficult to find a compatible SiC/SiCf material for wire production. In case of a carbide pellet assembly, 4 spacer grids are designed to be attached to the central pin. The central pellet does not contain nuclear fuel, it only serves as a structural element. The fuel pellet cladding is constructed of five layers. The hexagonal casing tube is also made of SiC material.

The following figure shows a comparison of the material composition and arrangement of the construction materials of the fuel pellet of the starter MOX assembly and the fuel pellet of the carbide assembly.

V4G4 Centre of Excellence

In order to intensify and make the ALLEGRO demonstrator design activities more effective, four nuclear research organizations of the Visegrád Group (V4) have decided to establish a legal entity, the "V4G4 Centre of Excellence", which is responsible for international representation of the project and its technical coordination. The V4G4 consortium was established in 2013. The purpose of the "V4G4 Centre of Excellence" is to coordinate activities in the preparation of the ALLEGRO demonstrator conceptual design. The main areas of the development were identified, and a plan of "V4G4 Centre of Excellence" activities and individual partners was established. Each Visegrád country implemented, implements and mutually coordinates national projects in order to achieve the highest possible efficiency of the funds spent.

The founding members of the "V4G4 Centre of Excellence" consortium are organizations from the Visegrád countries - the Slovak company VUJE, a. s., the Czech company ÚJV Řež, a. s., the Hungarian Academy of Sciences MTA-EK and the Polish research centre NCBJ. The associated members of the V4G4 consortium are the French company CEA, which is in the position of technical support for the members of the consortium, and the Czech company CV Řež, which is the operator of the S-ALLEGRO helium loop in Pilsen.

The objective of the "V4G4 Centre of Excellence" are the following activities:

- research of substantial safety related aspects and obtaining experimental results for the development of Generation IV nuclear reactors, in particular for the innovative concept of GFR (Gas Cooled Fast Reactors), for which the ALLEGRO demonstrator will be built and operated in the Visegrád (V4) region,

- promotion and popularization of a potential and perspective; technical, political and environmental issues related to the Generation IV reactors,

- contribute to the retention of qualified professionals in the field of nuclear energy by involving young scientists and technicians in demanding research and development activities.

- to help integrate nuclear research in Central Europe.

At the national level, the ALLEGRO Research Centre [4] was established in Slovakia with the investment of more than €16 million from the EU structural funds. In addition to the computational codes and the strengthening of the materials research infrastructure, a special Helium Loop of the Slovak University of Technology was built.

Slovak University of Technology - Helium Loop

The experimental helium loop is used for an empirical experimental verification of a natural helium circulation and a verification of the heat removal capability from GFR in a natural circulation mode. Helium has been selected as the medium used to remove heat from GFR by means of the primary circuit and Decay Heat Removal. The thermodynamic and hydraulic properties of the primary circuit will be verified on the technological circuit of the helium loop with a heat source to simulate the development of the residual heat in a shutdown reactor and with a heat-exchanger intended for residual heat removal.

The result of the set of experiments will be a database of measured characteristics of the primary circuit of the helium loop at different temperature and pressure of helium in the cold and hot branches, based on which it will be possible to compare the results of computational models with experimental data.

The experimental helium loop allows helium to be heated to the required temperature of 400 °C to 520 °C. The total installed power of electrical heaters (GFR) is 500 kW, with the possibility of regulating the heat output. Helium is cooled to the temperature of 150 °C up to 250 °C within the DHR heat-exchanger. The heat removal is provided by a gas-water type heat-exchanger. The helium loop is for the correct operation of DHR equipped with a cooling water source, which will ensure sufficient flow of circulating water through the cooler.

The helium loop contains a large number of technological openings for installation of thermocouples, pressure gauges, flow meters, determined for monitoring and evaluating the parameters of the primary and cooling circuit (DHR cooling). All measured quantities are led the control room by means of a busbar, from where it is possible to set the required parameter values and also to check and evaluate the measured quantities.

The SafeG Project

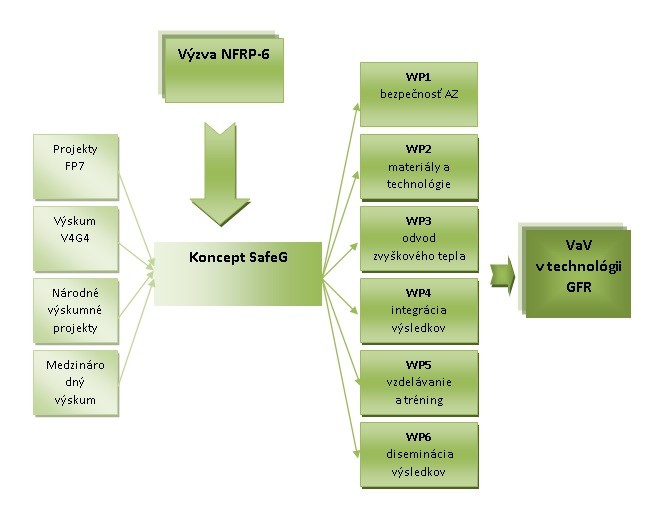

The call for proposals EURATOM Horizon 2020 (NFRP-6) was focused on the development and technical evaluation of safety enhancements to Generation IV systems stipulated by the Sustainable Nuclear Energy Technology Platform and the Generation IV International Forum. The SafeG project fulfils the objectives of this call for proposals by presenting a research and development programme focused on research of the safety of advanced GFR-type reactor technologies.

The SafeG Project, coordinated by VUJE, a. s. involves 15 partners from eight countries. The project partners are the top European research organizations as well as universities, including the Slovak University of Technology in Bratislava.

The SafeG project is designed to solve the open issues in the GFR safety concept and the design of the key ALLEGRO reactor safety systems. An important part of the design is the acquisition of new experimental data using state-of-the-art research equipment, as well as a large number of safety analyses and the study of physical phenomena, which will be carried out using specialized computer programs.

The SafeG approach is based on a long term and extensive experience of experts in the field of nuclear energy research and development, development and application of simulation tools, nuclear installations licensing, materials science and reactor safety in general. Outputs from the previous stages of the ALLEGRO demonstrator development will be used in the SafeG Project, in particular the outputs of the GoFastR Project, focused on the development of advanced GFR systems and the ALLIANCE and VINCO Projects solved in the previous European Union research framework programmes.

In the preparatory stage of the SafeG Project, the most urgent and unresolved issues and problems in GFR technology and the ALLEGRO demonstrator were assessed, taking into account in particular the progress and results of the "V4G4 Centre of Excellence" research and the results of national GFR research activities. The project concept is designed to find solutions to identified open problems, to make effective use of available resources, expertise and available experimental equipment.

The SafeG project is divided into six technical and one coordination package (WP). For better clarity, the following figure graphically describes the concept of the SafeG Project.

The main ambition of the SafeG project is to incorporate state-of-the-art technological innovations into the GFR concept, one of the six technologies of the Generation IV reactors, selected and supported by GIF, and to implement them primarily in the ALLEGRO demonstrator - one of the four reference demonstration units of Generation IV reactors supported by ESNII.

In accordance with the scope and objectives of the call for proposal, the ambitions and their innovation potential can be divided into four areas:

1) Completion of the ALLEGRO demonstrator safety concept:

- Core optimization in terms of neutronics, thermohydraulics and thermomechanics for the first (start-up) core, as well as for the next refuelling and a design of a diverse method of fission reaction control and reactor shutdown.

- Passive residual heat removal strategy, supplemented by the design of fully passive residual heat removal systems and residual heat removal research experiments performed on state-of-the-art equipment determined for GFR technology, such as the S-ALLEGRO helium loop.

2) Updating the ALLEGRO demonstrator design and GFR concept with state-of-the-art materials and technologies, such as innovative SiC-based fuel cladding materials, to refractory construction materials for the primary circuit and safety systems. Experimental data on material properties at different conditions and high temperatures specific for GFR will be obtained.

3) Joining the national research projects and creating a common platform for sharing knowledge, progress and coordination of activities in order to present these topics and results to the broader scientific community and develop them further at an international level, and thus shifting the cutting edge research to a new level.

4) Deepening the cooperation between Europe and Japan in the field of GFR research, by sharing knowledge on advanced refractory materials to cover fuel pellets and the key primary circuit components, as well as sharing efforts to test these materials under GFR conditions and implement them in the ALLEGRO design.

Conclusion and perspectives on the future

Nuclear energy is a determining factor in reducing greenhouse gas emissions in the electricity generation sector. Nuclear energy generates virtually no greenhouse gases at the place of its production and represents more than a half of the EU's low-carbon electricity. The development of new technologies in the production of electricity is an essential requirement to ensure a long-term and reliable supply of electricity.

The current extension of operation of the existing nuclear power facilities and the construction of new facilities require a strong scientific basis, education and training of the corresponding workforce. Competence can be maintained, and young professionals can only be attracted and educated if nuclear experts are able to participate in world-leading research and technological development. The excellent quality of the related scientific background and human resources is essential in countries that want to operate a nuclear installation safely and economically on a long term basis.

The ALLEGRO project requires a significant development of the state-of-the-art technologies. The construction of the ALLEGRO reactor itself requires the highest level of instrumentation and control systems operable in extreme conditions, special refractory materials capable of withstanding high levels of radiation, new optical measuring instruments, etc. ALLEGRO will be a testing facility not only for GFR technologies but also for advanced technologies requiring high temperatures (e.g. hydrogen production) or new types of nuclear fuels.

The research activities focused on the development of the ALLEGRO reactor have so far been substantially funded by private sources within the association of "V4G4 Centre of Excellence" and from the national projects of the individual Visegrád countries. The EU funded SafeG Research Project creates a precondition for involving research teams from across the EU and Japan. The project will also ensure a significant shift in the development of the ALLEGRO demonstration reactor concept.

The SafeG Project, coordinated by VUJE, a. s., creates realistic preconditions for ensuring the development of technical knowledge in the field of nuclear energy through the active involvement of young scientists and technicians.

Ing. Slavomír Bebjak

He graduated from engineering at the Faculty of Electrical Engineering and Information Technology of the Slovak University of Technology in Bratislava (2012) where he currently continues as an external student in the doctorate study programme and in his dissertation he deals with the Generation IV reactors.

Since graduating with an engineering degree (Master of Science) in 2012, he has been working as a researcher at VUJE, a. s., in the Nuclear Safety Division. He participates in the development of comprehensive computational models of nuclear power plants for thermohydraulic computational codes and performs safety analyses of VVER 440 type reactors. Since 2015, he has been a member of the international group for research of new types of nuclear reactors (V4G4). He was awarded the prize of the Ministry of Education, Science, Research and Sport of the Slovak Republic in the category of Scientific and Technical Team of 2017 for his contribution to the international research and development of the fast, gas-cooled ALLEGRO reactor.